PIPELINE INSPECTION SOLUTIONS

Taking UK Manufactured CCTV Systems Global

AM Industrial (UK) Ltd (AMI) was founded in 2006 by Arthur Jones, formerly Northern Service manager for UK CCTV systems manufacturer Telespec Ltd.

Arthur has gathered a vast knowledge over more than 20 years in the pipe inspection industry having undertaken activities from operating a CCTV rig for Avec in the 80s to performing a prestigious role as operations Director for well-known Warrington-based contractor General Underground Services. These roles meant that Arthur was well placed to launch his own technical support company.

AMI started out initially as a much needed technical support facility based in the UK’s Northwest. This was followed by the opening of a new division, AMI Southern in Surrey which heralded the opening a new much needed manufacturing facility. This facility enabled AMI to launch its own range of in-house designed and built, cost effective pipe inspection solutions.

The initial response to AMI’s products and services was overwhelming and in order to manage the workload AMI’s management structure was expanded with the appointment of Martin Woods formerly Sales director of Telespec Ltd joining the team.

According to Arthur Jones: “Pooling our joint experience of many years has enabled Martin and I to position the company so that we are now well placed to become a prominent player in the industry, both domestically and globally.”

The company recently relocated the Northern offices to a purpose-built site on the Woodrow industrial estate in Irlam, Manchester. This move will allow further expansion of the company’s technical support operations which will be coupled with the planned move in 2009 of the Southern Offices to a new manufacturing site. The manufacturing facility will enable a more streamlined approach to production to meet the ever-increasing demand for the AMI’s products.

Arthur went on to say: “We are proud to have formed a business that is a ‘true British thoroughbred’ that successfully develops and manufactures its products here in the UK. The UK has seen some truly high quality, innovative inspection products from central Europe being marketed successfully by appointed distributors. Whilst our products may not be deemed by some as innovative they do perform in both reliability and picture quality with proven comparatively, low ongoing cost of ownership and operation, which in the current climate is as important as innovation.”

Also, whilst being proud to be a British manufacturer, the company is also putting considerable input into the British economy with around 60% of its current production going to export into some 14 different countries worldwide.

EXPANDING GLOBAL INFLUENCE

Recent appointments of several new overseas business partners including: T&I Avenue (M) SDN.BHD for the Asia Pacific region, Pamtec Enviro for India and GSN Technologies Inc for distribution in North and South America only enhances the commitment of the company to the global distribution of its products. The current level of response to AMI’s products indicates an even better export growth year for 2009.

Commenting on the company’s growth Martin Woods said: “The main priority over the past two years has been the development and refining of the product lines to provide the highest standard possible in quality, reliability and cost effectiveness in the target markets. So, over this time the company has been fairly low profile in marketing its products and services. Now fully prepared, the time is right to properly launch our tried and tested product range. We have already supplied more than 60 of our SP100 Pan&Rotate cameras across the globe and customer feed back has been so positive we now have every confidence to proceed at full steam and increase our manufacturing quantities to meet the increasing demand for our products.”

AMI knows only to well how supply companies can often be so successful in growing their customer base to such an extent that the technical support falls short of customer expectations. Martin Woods explained: “We have already started to strengthen our service coverage by recruiting two additional service engineers to maintain the already rapid response time at both our Northwest and Southern service centres. As part of the next stage of corporate development the company is seeking to recruit a production manager to coincide with the impending move of the southern manufacturing facility later this year.

Having previously exhibited the AMI product range at the No Dig Live event in 2008, the response was well beyond expectation and new business has accrued as a direct result of the show. No-Dig Live was AMI’s first ever exhibition and because the products were so well received by so many potential customers the company has no hesitation in taking part in future industry related exhibitions throughout 2009. To further enhance its marketing campaign for 2009, AMI has started work on a totally new and much more informative website which is due to go live in April. This will also allow valued customers to purchase spares and accessories on line.

PRODUCT RANGE

AMI now manufactures a wide range of pipeline inspection solutions including:

- SP50 Pushrod system for use in 100/150 mm diameter pipes

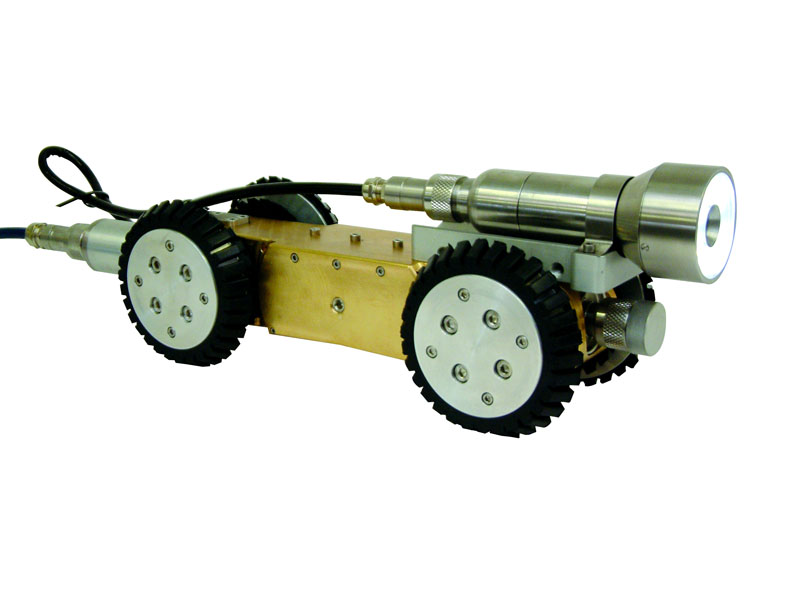

- SP75 MiniCam crawler system for use in 100/300 mm diameter pipes

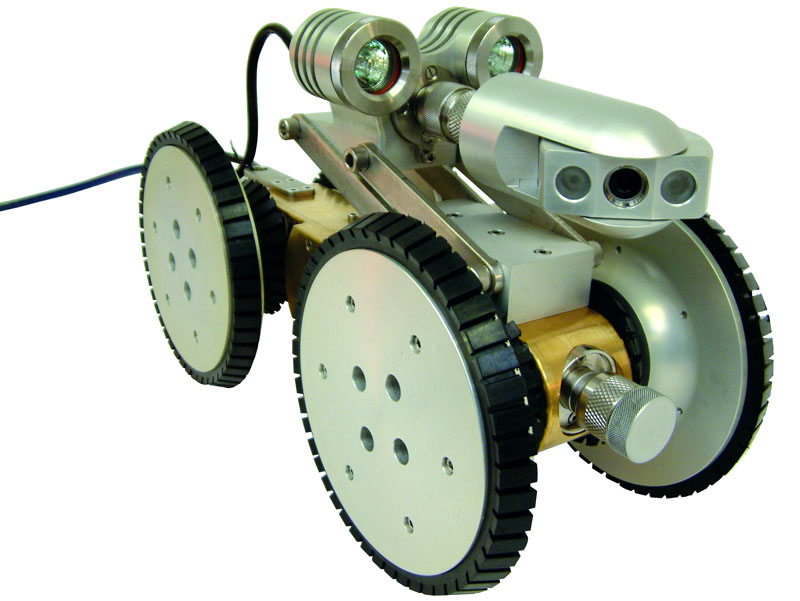

- SP100 Pan&Rotate camera

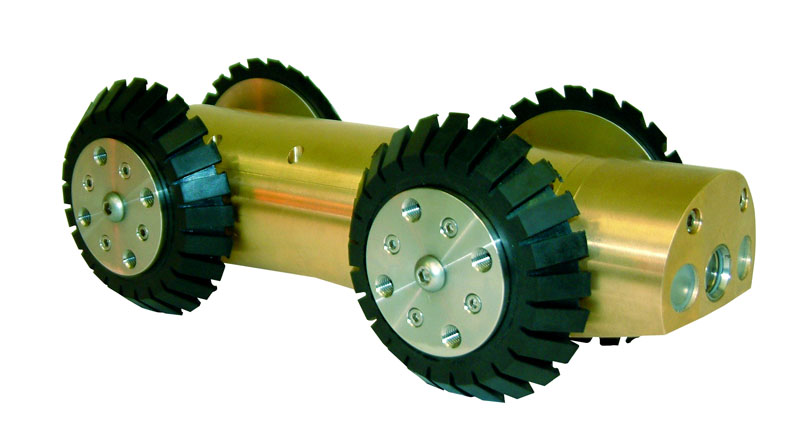

- SP150 Midi Crawler system for use in 150/1,000 mm diameter pipes

- SP300Z Mainline crawler system with Zoom for use in 300/2,000 mm diameter pipes

To compliment the range AMI is also the sole UK distributor for the Pipe Profiling Sonar (Model 1512USB) manufactured by Marine Electronics Ltd. The Model 1512 Pipe Profiling Sonar provides an acoustic method for profiling the interiors of liquid filled pipes or boreholes. This method does not require draining of the pipes as with camera surveys and provides accurate quantified data. The equipment comprises an underwater Scanning Unit (which may be skid, float, tractor or ROV mounted) and a compact USB interface unit. To complete the system a ‘Windows’ P.C. with a USB port is required to run the 1512 system software.

As a complete turnkey solutions provider AMI is also an Authorised reseller of the industry standard Wincan pipe defect reporting software with the pending launch of its integrated control system via a ‘ruggedised’ laptop with preloaded Wincan mobile software. Customised in house van fit-out is also scheduled to begin later in the year.

So to summarise, AM industrial can now offer a complete range of products to meet almost any inspection requirement. Not confined to just the water and waste pipeline sectors, AMI’s products lend themselves to other applications including boreholes chimneys, flues and non-destructive testing situations.

The AMI mid-range/mainline crawler unit fitted with an SP100 Pan & Rotate camera.

The SP50 Push Rod camera system.